Welds - new custom feature script in Onshape

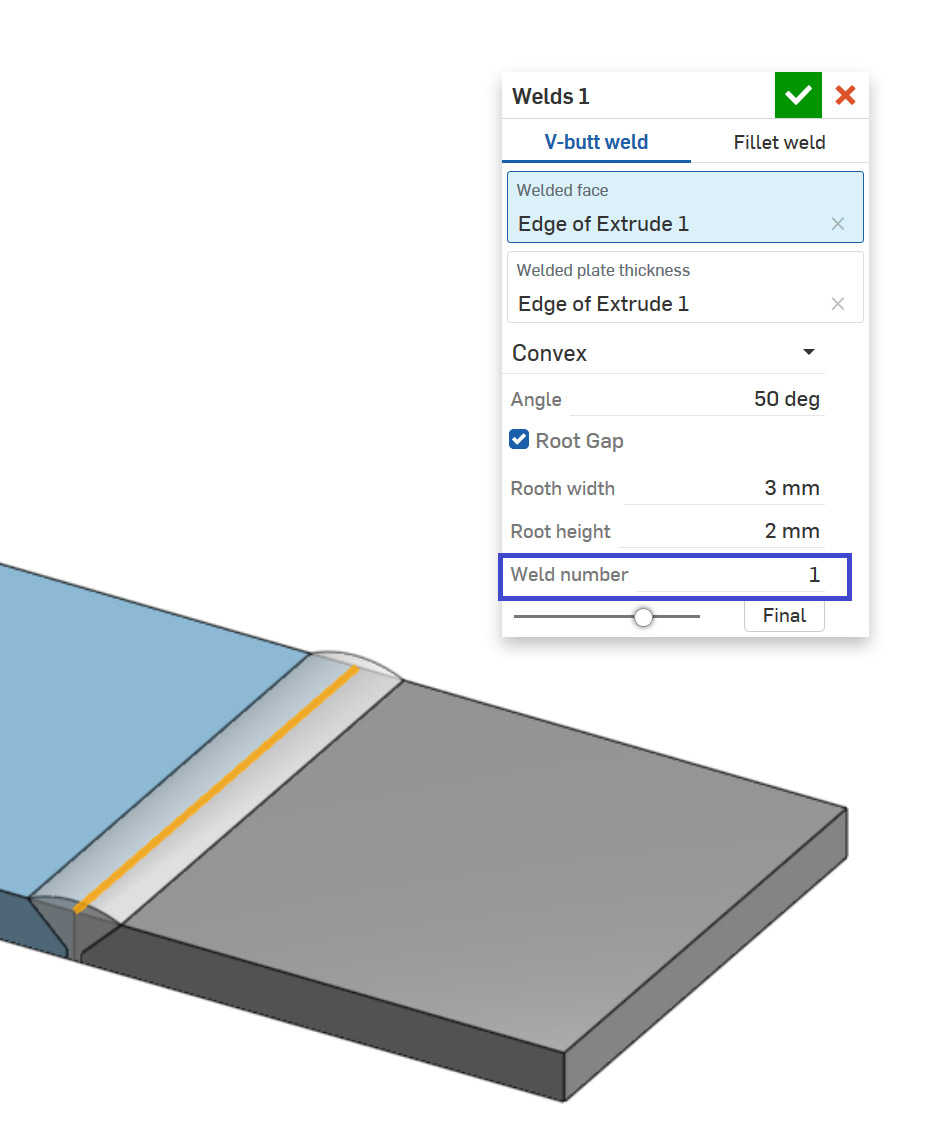

We like to make our work easier, shorten the time of performing monotonous tasks and we are constantly looking for new solutions we can offer to our clients. After a short brainstorm we have decided to create a tool, which will bring some benefits not only for us - constructors, but also our subcontractor's and clients' technologists. Once again we use Onshape program - which enables creating custom features by means of feature script. After first works there you can see direction we are heading. We are happy to introduce you with a prototype tool, which creates welds in 3D models.

But why all this?

After all, weld’s signs are being marked on drawings, nobody waste time to model them and everyone knows what is going on. There is some point in that - looking from constructors perspective. But let's take a look at a bigger picture - on whole process of manufacturing welded elements. Proposed solution will speed up technical documentation preparing as well as manufacturing welded elements.

Technological aspect

Preparing documentation is not only work of constructors. In the next stage, the technologists (among others) work on documentation. They give adequate allowances for cutting and machining, check whether the constructors' ideas can be implemented and how to do it using the machines available in the plant. Here is what we can improve in the process of preparing welding documentation:

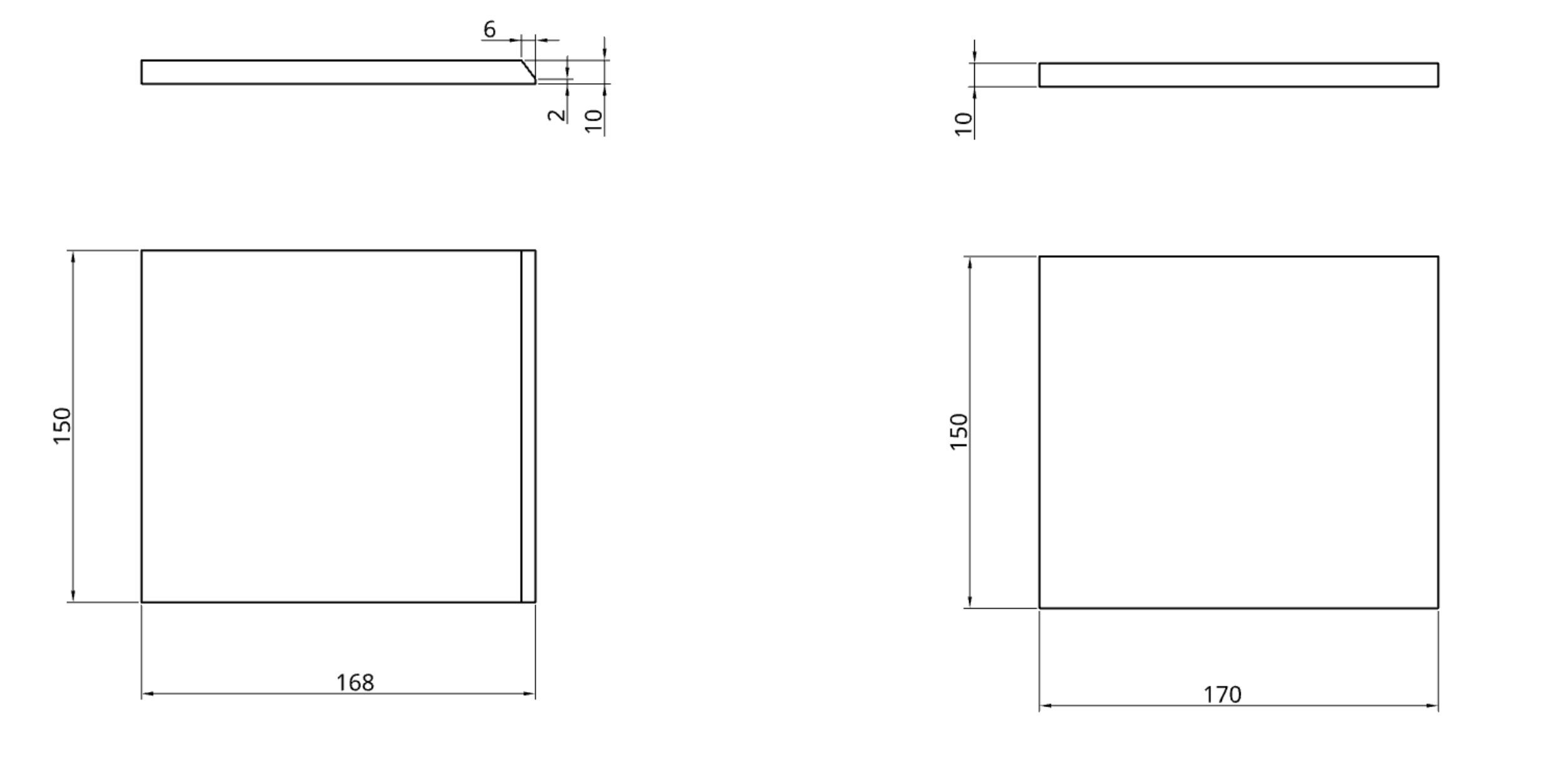

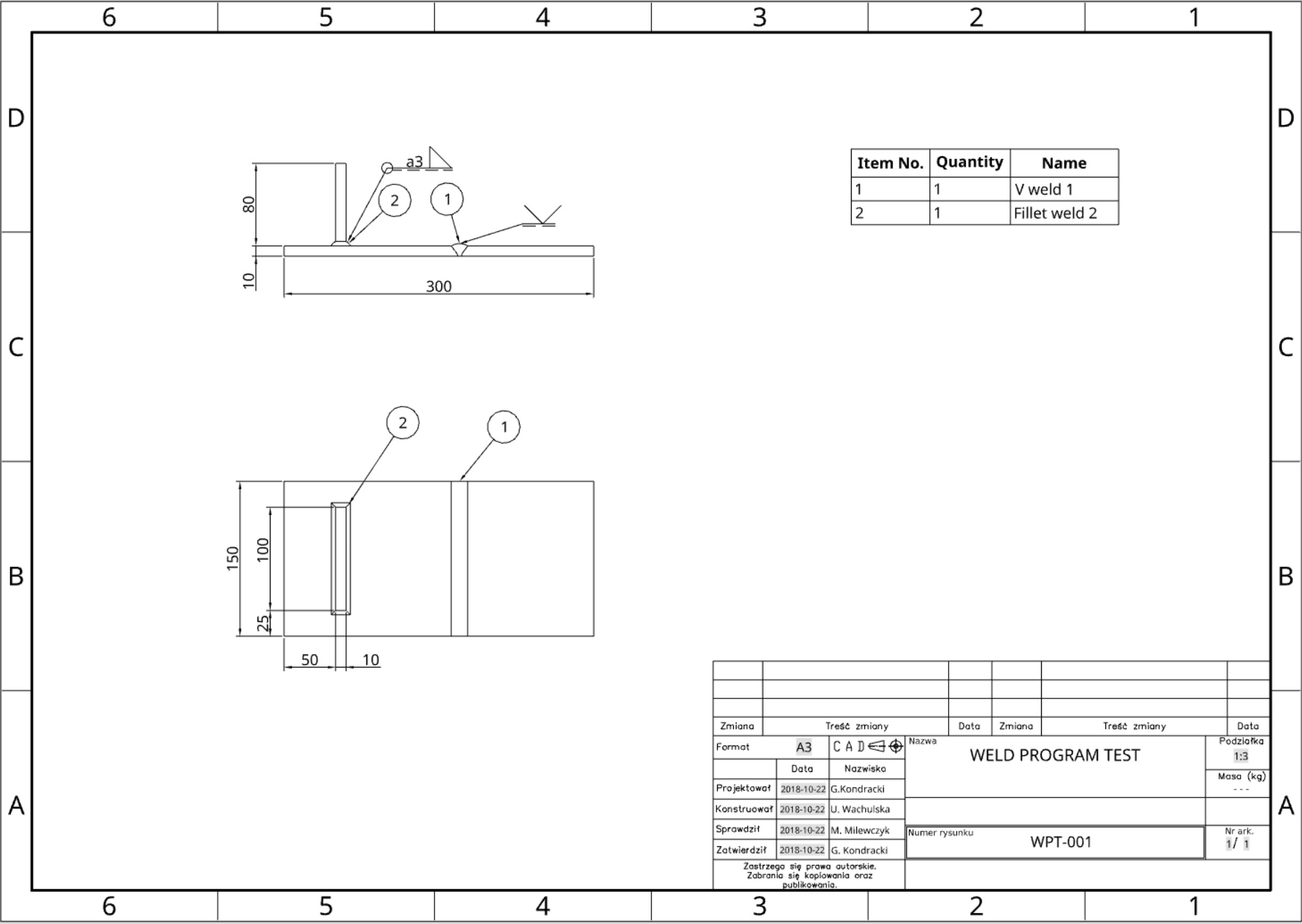

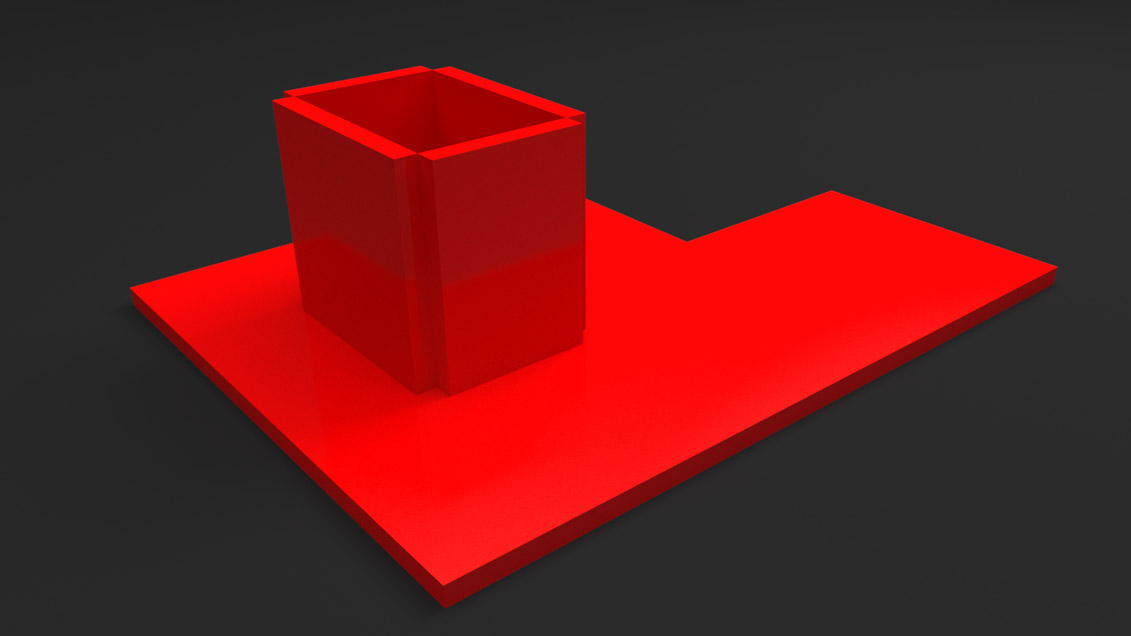

- We get the actual dimensions of plates: bevels in the right places, the reduction of overall dimensions (in case of v-butt welds with groove). Compare yourself on the picture below - on the left you can see sheet prepared for welding, on the right you can see the same sheet you get by marking welds on drawing only.

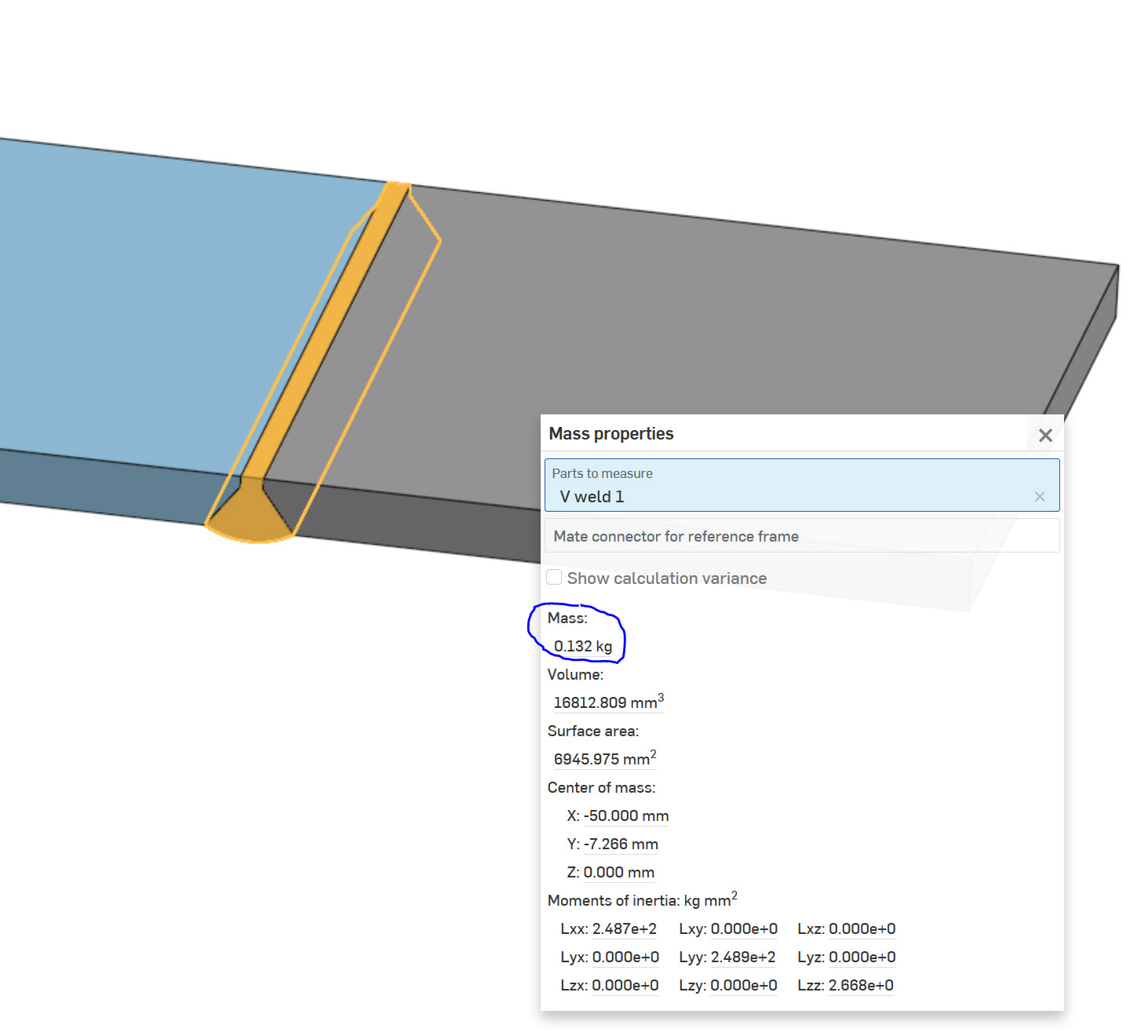

- The mass of welds can be read from the model. On this basis we can estimate quantity of welding wire and time needed for welding.

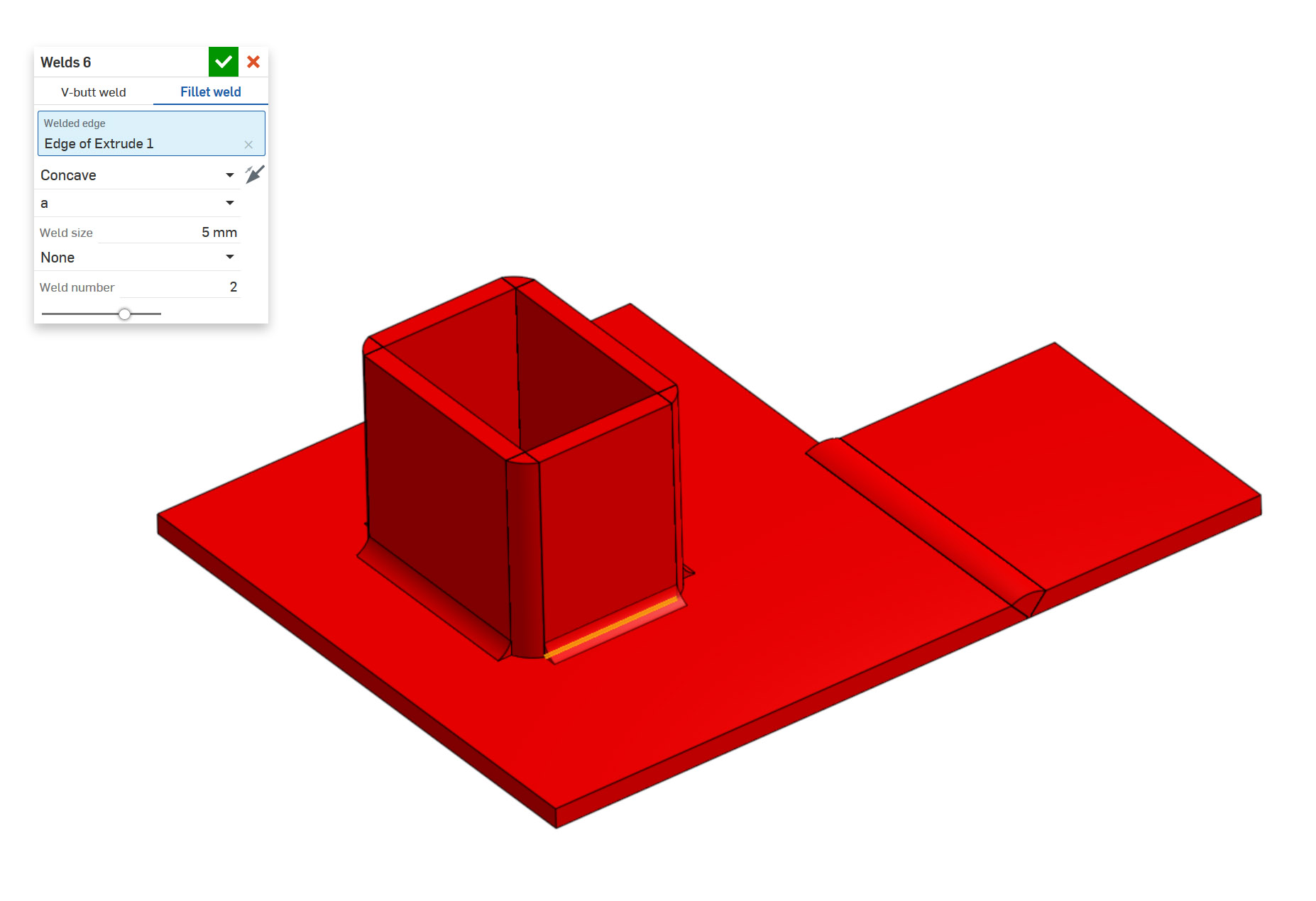

- for welded connections which require testing, it is necessary to give them numbers. Feature script produces welds names, with the number given during modeling - the whole can be easily transferred to the drawing and collected in the form of a drawing table.

Structural aspect

So what about the constructors? Engineer must spend a little more time on the model (little, but still ...), generate a list of welds with masses and numbers. Only new responsibilities? Nothing more wrong - this is what we give in return:

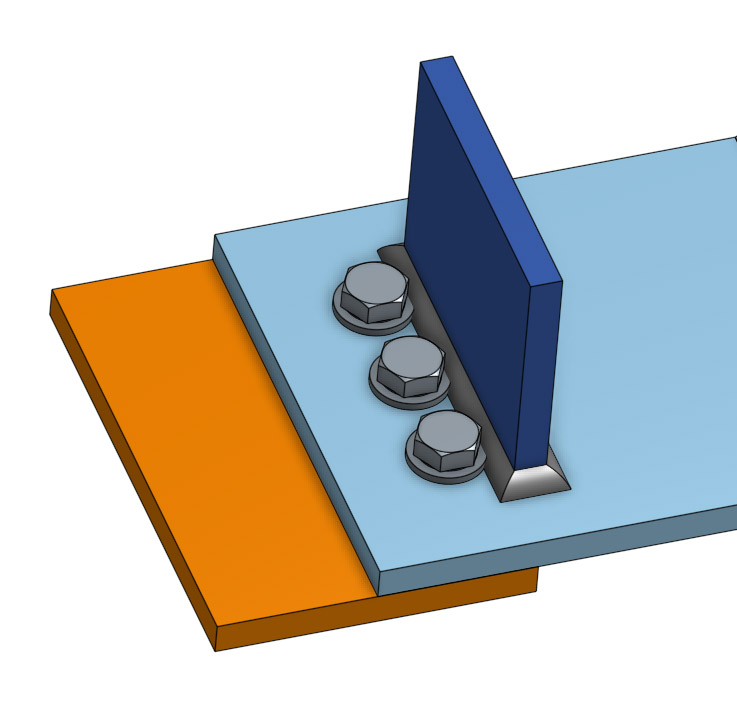

- thanks to the welds visualization, it is more easy to check if there are adequate access to perform these connections. Before the constructors had to predict how to carry out the welds also by marking welds only on drawings-in this case seeing the welds on the model will be easier. One of the advantages is minimalization the risk of mistakes, especially with more complex constructions. In the future we want our program to have a database in accordance with the welding technology instructions (WPS) of the production plant, which will further simplify preparation the of welds.

- before the constructors had to determine the numbering of welds and give their masses. Today - depending on the company procedures, it is the responsibility of constructors or technologists. With the feature script there is no need for manual numbering or mass counting.

- it will be easier to check the presence of collision, e.g. with screws, cooperating elements - which will be especially appreciated by less experienced employees

Educational aspect

By creating a more realistic model of welded constructions, we can immediately see how the element will be produced. This will be helpful when implementing young employees or trainees.

Visual aspect

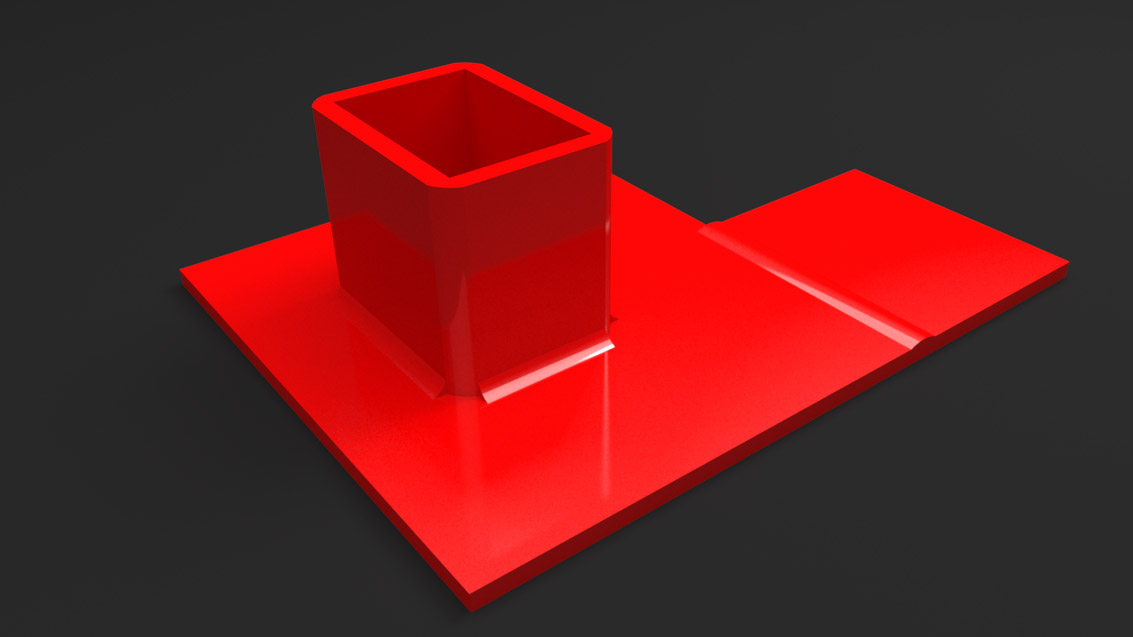

From the documentation point of view- the least important. But having prepared model, we can create more realistic visualizations of our designs, please compare yourself:

Future plans

Our program currently has many limitations - we wanted to test our ideas on it and get to know the opinions of other constructors and technologists.

After the first tests, we see many applications in which our script will work and we want to develop it. First of all, we will enable it to be used for sheets angled at any angle with respect to each other and we will extend it to other types of welds.

Out of concern for the appropriate substantive level, we invited welders' engineers for consultation.

For now, geometric data of welds can be entered when generating welds. But we want these data and limitations on their use to be included in the csv file. This will ensure easy matching of welds to different technologies, according to the requirements and capabilities of customers.

Next, we plan to expand our program with other types of welds and welds according to other standards.

We still have a lot of work to develop our script - but today we invite you to test. If you have any comments about how the program works or ideas which would be worth to implement, please contact us.

Script can be found here: Script

If you are enthusiastic about Onshape feature scripts - we are open to cooperation on writing the other functions. We are not experts in this field, you can certainly improve something in our code - maybe we will do it together?